SERVICES

ENSURING PERPETUAL PROFITS & GROWTH IN MANUFACTURING THROUGH RESULT ORIENTED CONSULTING & EXECUTION SERVICES

The prime objective of a business is to manage a perpetual profitable growth in the current competitive environment. However, business variables have become too complex to manage with ease, for last few years due to globalization, technology convergence and intense competition. This accelerated change has brought in a lot of stress in the present business system. The effective Execution has become the key to succeed.

We understand the depths and breadths of business processes, support new ideas and technologies but with focus on traditional values with results and return on investment (ROI) on mind. Always with our eyes and mind to the future, we help our clients reap maximum benefits from their core-competence and identify weak areas, create a time bound road map to improve and turn weakness into core-strength. Inter Alliance Werardt has a proven track record to execute excellence in client`s business operations.

CONTEMPORARY CHALLENGES IN TODAY`s MANUFACTURING SECTOR...

- Rapid product obsolescence.

- Integration of IT in manufacturing.

- Globalization.

- Emerging new business models.

- People involvement, motivation and sustenance.

- Management push for quick ROI.

- Lack of sense of ownership by employees.

- Increment proportion in input cost is more than selling price.

Profitability, Productivity & Efficiency through CONSULTING EXECUTION & SOFTWARE SERVICES

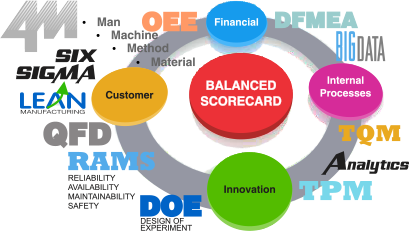

This all begins with our core competence to align 4M`s (MEN, MACHINES, METHODS & MATERIAL) supported by relevant application of excellence tools, our business solutions are WCM complaint

4M ALIGNMENT

PEOPLE ALIGNMENT

PEOPLE ALIGNMENT

People at all levels are the essence of an organization and their full involvement enables their abilities to be used for the organization’s benefits. All 4M alignment initiatives are being implemented by using following parameters effectively.

- Defining Profile

- KRA`s, Roles, Responsibilities.

- Performance enhancement evaluation and appraisal.

- Learning requirement.

- Skill enhancement.

- Learning evaluation - Kirkpatrick method.

- Transition to transformation.

- Psychometric testing.

- LMS.

- People / Team motivation.

- Reward & Recognition system.

- Retaining people.

- Employer branding..

- Customized HR policy documentation.

- IT integration.

PLANT PERFORMANCE

PLANT PERFORMANCE

The effective performance of a manufacturing plant directly affects the profitability of an organization. Managing optimum machine performance has become very challenging due to emergence of advanced technology and complex processes. The need for precise machine performance information on time has become a crucial input parameter for contemporary CEOs. All 4M alignment initiatives are being implemented by using following parameters effectively.

- 8 Pillars of TPM.

- 5S, Kaizen.

- Jishu Hozen.

- Machine/Equipment Information-:

- Preventive Maintenance.

- Quality Maintenance.

- MTTR.

- OEE.

- RCM.

- Reliability.

- Availability.

- Maintainability.

- Safety.

- Reverse Engg.

- CFD.

- CBMS.

- Warranty Analysis.

- Machine Failure Forecasting.

RESOURCE MANAGEMENT

RESOURCE MANAGEMENT

The efficiency of any organization depends upon the availability of right material, in right quantity at right time and at right price. Material offer considerable scope for reducing cost and improving profit. Improving return on investment depends on the effective utilization of materials. All 4M alignment initiatives are being implemented by using following parameters effectively.

- List of material /spares.

- Classification of material spares.

- Stock optimization policy.

- Specification of material/spares.

- Routine vendor evaluation / identification / replacement initiative.

- Search for alternative cost effective materials / spares.

- Regularized data recording of materials / spares to be maintained.

- Proper storage capacity.

- Careful material handling.

- Disposal of waste material.

- IT based solution for material management.

- Regular vendor audit.

- Regular material testing & vendor up-gradation programs.

PROCESS MANAGEMENT

PROCESS MANAGEMENT

Identifying, understanding and managing interrelated processes as a system contributes to the organization’s effectiveness and efficiency in achieving its objectives. A desired result is achieved more efficiently when activities & related resources are managed as a process. All 4M alignment initiatives are being implemented by using following parameters effectively.

- Entire manufacturing process flow to be documented.

- Documentation of SOPs regarding all activities.

- Interrelated systems to be defined and documented.

- All the activities to be carried out as process and documented.

- The data related to activities to be managed in a robust IT system (some good ERP).

- Routine analysis of data to be conducted to determine the routine MIS.

- Continuous and closed loop follow system based on MIS.

- Continuous improvement with horizontal deployment should be part of the culture.

- Alignment of quality policy & quality objective with organization vision & mission.

- Study of quality manual, control of documents and records.

- Effective decision making based on the analysis of data and information.

- Using statistical methods for decision making for complex issues in the process.

- Evaluate cp, cpk, z value and sigma levels of various processes for precise decision making.

CLIENT TESTIMONIAL

We have engaged Mr. M.K. Khanduja, for " Time & Motion "Study for our Aurangabad Plant and also facilitate " Lean Manufacturing" Training for all our employees in the plant. We found Mr. Khanduja’s approach with respect to the above study very scientific and comprehensive which is praise worthy. Also the training imparted by him was found to be very value adding by the participants. We wish him all success in his endeavors.

Sanjeev Dixit

Vice President – HR for Allied Blenders & Distilleries Pvt. Ltd.

Because of the technical expertise you have and the attitude to understand the objective and resolve the issue, project is completed in targeted period. With this I thank you for the prompt responses given by your team. Wish you great success in all your projects.

Mr. JV Waghmare

Electronics and Instrumentation, Cipla Limited, Kurkumbh

Mr. Khanduja had been associated with Dantal Hydraulics Pvt Ltd.,for the execution of Plant performance improvement practices. A reduction of 25% breakdown time and 15% spare parts consumption has been observed by the manufacturing excellence practices mutually implemented by him and my team. He is a committed professional for ensured delivery.

Yogesh Tyagi

Agm Plant Engg. , Dantal Hydraulics Pvt. Ltd

This is to certify that Inter Alliance Werardt Consultants have conducted the Lean Manufacturing project in our production units at Kinauni, Distt. Meerut, Palia, Distt. Lakhimpur and Kundarki, Distt. Gonda. There has been substantial improvement in 5S, Kaizen and elimination in non-value added activities. The lead time has been also improved in the process. Customization of project and connect with target audience is their core competence. Inter Alliance Werardt professionals are committed and punctual.

Jitendra Kumar Sharma

Sr. General Manager – HR, Bajaj Eco-Tec Products Ltd

We have been using FTM successfully for the last 5 years and has been very useful in analyzing Machine Breakdown problems and Preventive Maintenance.

Mr. PC Mishra

Divisional Manager, Mico Bosch Group, Nasik

We have been able to achieve a Plant level MTBF of 181 days, which is quite a record. FTM has helped us analyze, plan and execute our strategies well.

Mr. Madhav Kandekar

Sr. Manager – Maintenance Seagram Disteilleries, Nasik

We have got more control operationally with the use of FTM and can easily quantify our work and plan our schedules along with a better visibility over spares utilization.

Animesh Ghosh

Deputy Maintenance Head, Alstom Projects India Limited

Manufacturing excellence project planned and executed by Mr. Khanduja in our organization has brought in measurable improvements in Mfg. operations, Quality, HR and Reverse engineering. Mr M.K. Khanduja has a deep understanding of advanced excellence techniques like Six Sigma , Reliability Engg, WCM and Analytics etc. wish him all success in his endeavors. In recent project of manufacturing excellence in Bonn Group of Industries we can observe big change.

Pankaj Aggarwal

Vice President, Bonn Nutrients Pvt. Ltd.

Our machine breakdown was reduced by 40% within a time spare of 5 months leading to good productivity and better profits.

Gurmeet Singh

CEO, SS Foods Industries